With epoxy flooring for garage floors, the best step you can take to create the most durable and toughest flooring for your garage is to apply a garage floor epoxy coating.

Unlike traditional garage floor paint which simply dries on the surface it is applied to, our 100% solids, high build garage floor epoxy coating undergoes a chemical reaction that results in a thick coating, tightly bonded to the prepared surface.

Our epoxy garage floor is the number one choice for floor paint in Vancouver, Metro Vancouver, Surrey, Burnaby, Coquitlam, and Port Coquitlam as it protects and seals whilst offering an attractive, decorative, professional finish.

You are not only left with a quality flooring that looks nice, but also one that can withstand abrasions, stains, impact, and chipping.

Gone are the days you have to worry that dropping a heavy tool or dragging the lawnmower out of the garage will result in unsightly scrapes and scratches on your epoxy garage floor coating.

What is Garage Floor Epoxy?

An epoxy garage floor coating does not paint. Paint for garage floors is a latex acrylic product. Some paints will have a small percentage of epoxy added to the mix to make it more durable than standard paint, but it is still painted. These are known as epoxy paints or 1-part epoxy paint.

Epoxy is an actual thermosetting resin that is applied as a coating. It is formed when you mix one part epoxide resin with a one part polyamine hardener. The hardener acts as a catalyst and is what gives epoxy its strength.

Unlike paint that has to dry, epoxy actually cures. When the two parts are mixed, a chemical reaction is started which creates an exothermic curing process. This curing process produces polymer structures that are closely cross-linked giving epoxy its superior strength and durability. The end result is a coating that is much thicker than paint and bonds tenaciously to a properly prepared surface.

Epoxy Flooring for Garage Floors

Garage floor epoxy is resistant to moisture, dirt, chemicals, and salts making it ideal for those living in climates where rain and snow are common as the seasons change.

Garage floor epoxy flooring is a tough, long-lasting coating that you paint onto the concrete.

An epoxy garage floor resists grease, oil, and many other substances that would ruin ordinary paint. Garage floor epoxy paints clean easily and can be found in a variety of colors (if you look hard enough), so you can keep your garage floor paints sparkling clean and attractive for years.

Benefits of a Garage Floor Epoxy Coating

After the initial installation, epoxy will not need to be redone for an extended amount of time. The coating endures longer than tile, carpet, and wood flooring because of its resistance to shock, water, and even stains. The appearance of epoxy will last for years because of its durable and protective qualities.

If you want to establish a flooring that you won’t have to replace regularly over the years, epoxy is a practical option for preparing garages and basements for long-term satisfaction. The longevity also reinforces the cost-effective advantages of this coating application.

Epoxy coating one of the best finishes for your garage floor, Besides looking nice, the hardened and thick application that you get from epoxy creates a coating that is very durable and resilient to impacts, chipping, chemicals, stains, and surface abrasion. You don’t have to panic about damaging the floor if you drop a wrench or a bicycle falls over

The thicker coating also does a great job of covering over minor imperfections such as small spider cracks and flaws in the concrete. Because epoxy is a topical sealer, it is also anti-dusting. Much of the dust in a garage is created from the powder that a cement floor can shed. Normal traffic on bare concrete can kick up this dusty powder that has a tendency of collecting on cars, tool benches, and storage items, as well as being tracked into the house.

As a topical coating, it is also naturally moisture resistant. This is a great benefit for people who live in snowy climates. It makes for easy cleaning of icy brines and road salts that can collect on the floor during the winter. Just a little mild soap and water is all it takes. Dust and debris can be collected with a dust mop or soft broom when the floor is dry.

Depending on whether you added colored acrylic flakes to the floor and the type of topcoat used, some surfaces can be slippery when wet. For people who live in drier climates, this usually isn’t an issue. If you want some extra grip, however, you can add slip-resistant aggregate to the final coat that will create a non-skid surface.

Epoxy Flooring for Garage Floors is both chemical and stain resistant, oil, brake fluids, anti-freeze, gasoline, and other caustic car chemicals can easily be wiped up without worry – even if it sits for a while. Rolling tool boxes, jacks, and jack stands will not damage the floor either. It also brightens up the garage environment because it is very light reflective depending on what type of finish you choose.

As tough as this type of garage floor covering is, it’s not resistant to everything, however. Welding is hard on epoxy because it can create burn marks from the hot slag that falls on it. It’s also not a good choice for garage floors that have moisture issues. The rate of moisture vapor transmission from underneath the slab can cause the epoxy to delaminate if it is too high.

How Garage Floor Epoxy Is Applied

Test Your Concrete for Moisture

Lift the corner of a plastic bag that’s been taped to the garage floor for 24 hours. If it’s dry underneath, you can proceed with a garage floor paints epoxy coating. If you see moisture under the plastic, don’t coat the floor with epoxy; water pressure will break the bond.

Analyze the floor and weather before you even consider an epoxy garage floor, test to determine if dampness is coming up through the concrete from the ground. If moisture is evident, your floor isn’t suitable for epoxy. Also, forgo the project if a concrete sealer was previously used (you’ll know a sealer has been used if water beads up when applied to the surface).

If you’re dealing with a new slab, you must wait a minimum of 28 days, preferably two months, for the floor to cure and dry thoroughly before applying epoxy flooring. And if you’re dealing with a previously painted floor, the best advice is to remove the paint, especially when you’re applying a solvent-based epoxy garage flooring paint that could soften any that remains.

If your concrete passed these tests, make sure the weekend weather passes, too. The temperature of the concrete must be a minimum of 55 degrees F, with an air temperature between 60 and 90 degrees for optimum garage floor epoxy curing/drying.

Epoxy garage floors require good floor preparation which is critical for a successful coating. This usually involves some form of either floor grinding, shot blasting, or acid etching of the floor to profile the concrete for the epoxy. It’s very critical that it is done right or the epoxy coating will not adhere properly. Patching or repairing any cracks or other damage to the concrete before the epoxy is applied is required as well.

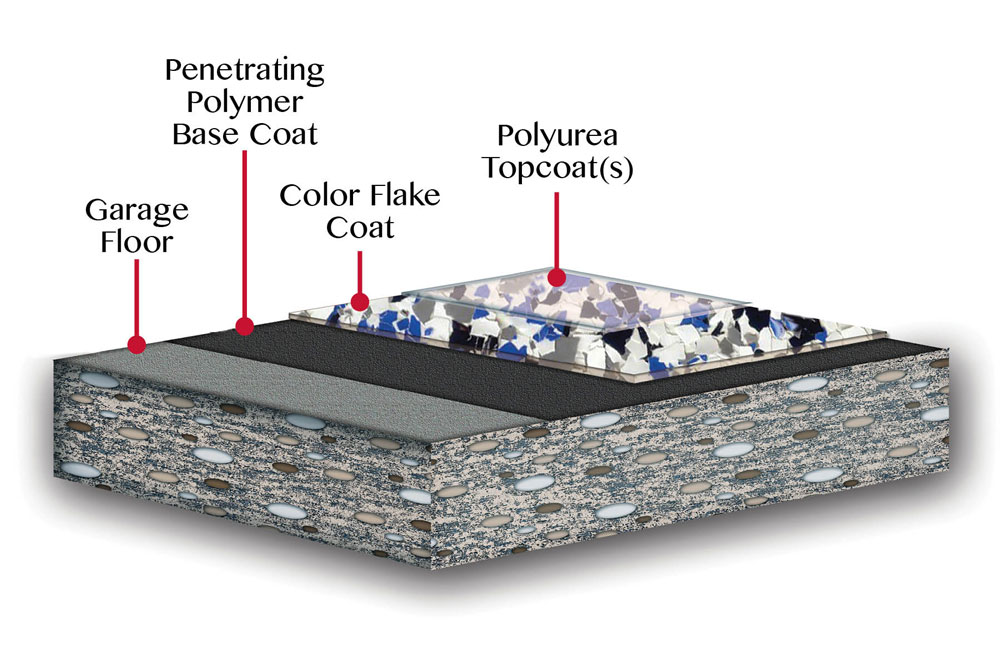

Quality epoxy flooring for garage floor systems usually involves multiple coats to ensure a very tough and resistant coating that will last for years. Many times this will involve an epoxy primer which is applied first.

The primer is what binds to the concrete to provide adhesion for the subsequent layers and provide for a higher build. Some primers will also act as a moisture barrier for those cement floors that are somewhat susceptible to moisture vapor that moves up from the soil through the concrete to the surface.

The next coat is the color coat or base coat. This may sometimes be applied without primer depending on the manufacturer’s recommendations. This coat will also receive the application of colored acrylic paint chips to add density and texture if so desired. The final coat is the clear topcoat. This is what gives the finish that glossy look and depth that these floors are known for.

However, the reality of this challenging project is, one, not all concrete floors will hold epoxy floor coatings, and two, preparing concrete for epoxy floor coatings can be labor-intensive and tedious.

Furthermore, it prevents unpleasant dirt and dust from spreading throughout your garage and on your possessions, typically caused when cracks and other flaws in your concrete create a powder and dust that is kicked up by foot traffic or vehicles.

A garage floor coating acts as a sealer, thus making dusty garages a thing of the past. Your garage will be safer, cleaner, and much easier to clean.

Western Canada Coatings is proud to offer a large variety of epoxy flooring for your garage and has tens of thousands of satisfied customers across the country.