The difference between epoxy and polyurethane coatings is that both are good for you to prevent abrasion and damage from chemicals and oils. Both epoxy and polyurethane have washable, anti-wear and light-reflecting properties, as well as long life, but both have advantages over each other in their application, such as epoxy flooring in three chemical formulas: water-based, solvent-based, and 100% solid. It is used as a floor and seal

Each of these 3 chemical formulas provides varying degrees of thickness from 3 mm to 9 mm for coating. Epoxy coating is suitable for use on concrete substrates and you can even use it in the epoxy coating when you want to replace your worn concrete.

Polyurethane flooring is available in a variety of formulations and is the best choice for use as flooring, although approximately 60 to 70% is left. A polyurethane coating is only about two to three centimetres thick. It is not adjustable like epoxy coating. This flooring is much more flexible than epoxy flooring, ie it is 300% more flexible than epoxy. This is a great advantage because you can use it. Sprayed paint and this thin thickness of polyurethane epoxy coating is not a reason for its weakness

Polyurethane coating has high flexibility compared to epoxy coating, and this flexibility absorbs the impact of the plate.

Advantages of POLYURETHANE COATING

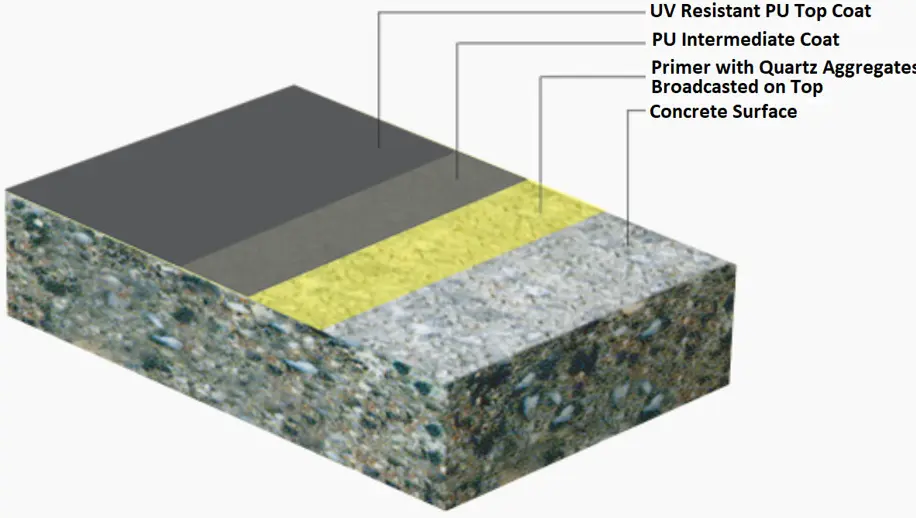

Polyurethane, like epoxy, is a thermogenic polymer with high performance and coating. It is commonly known as abbreviated urethane, although it is technically incorrect and there is actually a big difference between polyurethane and urethane. These products are very popular in the group of floor coverings due to their high resistance to sunlight (UV) rays as well as acid rain. Also, the characteristic features of these floors are their very short drying time, high resistance to moisture and adhesion, excellent on all types of surfaces and coatings as a final layer to cover surfaces that are exposed to direct sunlight and harsh weather conditions. Are. Polyurethane resin floor paints are available in different types; Available in one-component and two-component categories, both categories can include solvent-based and water-based powder paint products. There are also solvent-free PU Floor Paints, which are a two-component paint group. Two-component polyurethane paints have a very beautiful and eye-catching appearance and are free from any problem of Portuguese skin, which is one of the major problems of powder paints.

Advantages of EPOXY COATING

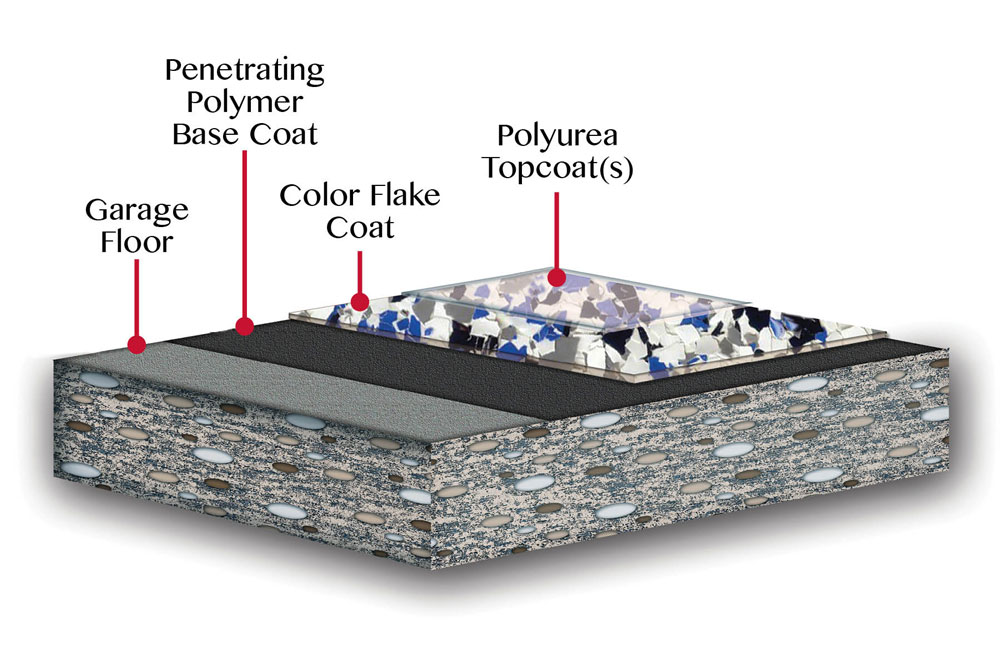

Heat-curable polymer epoxy in three different water-based, solvent-based and 100% solid formulations; Available for garage floor and sealer. These compounds can be applied in different thicknesses from 3 mm to more than 7 mm to create a uniform coverage for a garage floor. Epoxy bonding is well suited for concrete preparation and can sometimes be used as a regenerating agent for old or worn concrete that requires a new surface.

The best epoxy formulations are 100% solid and provide a very impact-resistant and thick surface. This thickness fills small hair cracks and floor imperfections as well as protects the substructure. It also performs well against hot tires, scratches and abrasions. Although some epoxies are formulated to withstand UV, they will eventually turn yellow or purple when exposed to sunlight. This is something you should consider when choosing to floor for your garage in the difference between epoxy and polyurethane coatings.

From a form and function standpoint, epoxies are very good at three things

- Bonding to Concrete: Provided the concrete substrate is properly prepared to receive a coating, epoxies are excellent for mechanically bonding to concrete. This creates a well-adhered system base that will allow subsequent build and topcoats. A complete coating system is only as good as its initial bond to the concrete substrate. Of course, concrete preparation is a crucial part of establishing a proper bond. We recommend concrete preparation by mechanical means, such as diamond grinding or abrasive shot blasting methods.

- Build/Thickness: Epoxy build coats are typically installed at 8 to 15 miles per application. This thickness allows the coating to chemically bond to the epoxy primer and is thick enough to self-level and fill minor concrete blemishes and hairline cracks. Depending on the desired performance requirements and condition of the concrete, more build coat applications may be desired. Upon curing, the epoxy build coat(s) provide a hard, durable surface.

- Installation & Performance: Upon curing, the epoxy build coat(s) provide a hard, durable surface with good impact resistance. Epoxies are fairly easy to install, exhibit ample working time, and are fairly cost-effective when compared to other industrial flooring solutions.

Although polyurethane has many advantages over epoxy, it does not cover concrete well and is not thick, and does not act as a surface coating to fill small cracks and crevices in the surface.

So what should you do?

As a rule, it is believed that by using polyurethane and epoxy to cover the parking lot floor, you will get your maximum performance. Epoxy is best used to make the thickness of the floor covering, which is then used with polyurethane as a light coating to protect the epoxy layer from yellowing and provide a more uniform surface and strength.

So, in addition to the fact that you can do a layer of epoxy coating for your parking lot, a combination of epoxy and polyurethane is almost always the best answer and solution to get the maximum useful combination of both types of materials. The result is a high-quality performance of the parking cover layer, which will show durability and longevity against all kinds of abrasions and erosion in the parking lot for many years.